Some 2014-2016 Malibu models equipped with the 2.5L 4-cylinder engine (RPOs LKW, LCV) may have an illuminated Check Engine MIL and the following DTCs set in the Engine Control Module (ECM): P305F (Dual Battery Control Module Performance), P058B (Battery Monitor Module Current Monitoring Performance), and P058D (Battery Monitor Module Voltage Monitoring Performance).

Depending on the DTC that is set, the cause may be:

- A loose ring terminal at the negative battery terminal

- Fretting or corrosion on female terminal pins in the 4-pin connector

- A loose splice in the harness ground circuit

- A defective Dual Battery Isolation Module

DTC P305F

If DTC P305F is set, check the state of health of the auxiliary battery using the EL-50313 Midtronics GR8 Battery Tester/Charger. If the state of health of the batter is low, replace the battery.

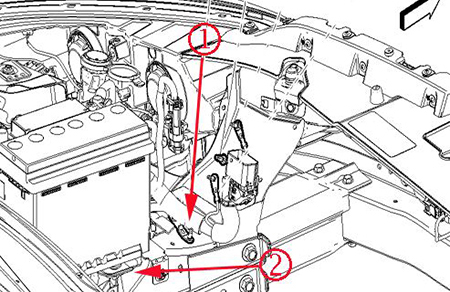

If the state of health of the auxiliary battery is good, check ground resistance from the Dual Battery Isolation Module (DBIM) to G103. Wiggle the harness and negative battery terminal connections to look for varied resistance values. (Fig. 2, #1)

If the resistance is greater than 0.5 ohms, or changes more than 1 ohm, inspect the ground connections and the splice in the harness about 1.5 feet from the connector end. Repair any poor connections.

If the resistance is less than 0.5 ohms, verify that the engine harness is not pinched underneath the main battery tray. (Fig. 2, #2)

Fig. 2

Fig. 2

If none of these conditions are found, replace the DBIM. The DBIM is located on the fuse block assembly, which requires replacing the Battery Distribution Fuse Block and wiring harness connector.

DTCs P058B and P058D

If DTCs P058B and/or P058D are set, check the orientation of the grounding ring (Fig. 3, #1) for circuit 150 to the B110 Battery Sensor Module. (Fig. 3, #2)

Fig. 3

Fig. 3

If the ring is contacting the sensor module, reposition the terminal away from the sensor module and tighten the bolt to 44 lb.-in. (Fig. 04)

Fig. 4

Fig. 4

Also check ground resistance from the DBIM to G103. Wiggle the harness and negative battery terminal connections to look for varied resistance values.

If the resistance is greater than 0.5 ohms, or changes more than 1 ohm, inspect the ground connections and the splice in the harness about 1.5 feet from the connector end. Repair any poor connections.

If the resistance is less than 0.5 ohms, replace the Battery Distribution Fuse Block and wiring harness connector.

Refer to Bulletin #18-NA-367 for additional information and part numbers.

– Thanks to Calvin Kohring