The new 2019 Chevrolet Silverado 4500HD, 5500HD, 6500HD chassis cab models (Fig. 1) are the newest entries in the medium-duty truck market. The trucks are available as regular and crew cab models in Work Truck (WT) and LT trim levels, both in 2WD and 4WD configurations. There are a range of wheelbases and GVWRs.

Fig. 1

Fig. 1

The Silverado chassis cab features a clean top-of-rail design with no protruding welds or brackets for smooth, integrated upfits. Plus, the single-piece frame rails and painted chassis provide enhanced durability. (Fig. 2)

Fig. 2

Fig. 2

Duramax Diesel

The standard 6.6L Duramax diesel V8 engine (RPO L5D) (Fig. 3), paired with an Allison 6-speed automatic transmission, generates 350 horsepower and 700 lb.-ft. of torque. The engine uses Ultra-Low Sulfur Highway Diesel Fuel and/or B20 biodiesel with a biodiesel content up to 20% by volume.

Fig 3

Fig 3

The truck features a tilt-hood opening design for easy access to the engine. Undo the two hood latches on each side of the hood and pull at the front of the hood (above the grille) to tilt the hood and fenders forward. The hood actuator strut lock, located near the bumper on the passenger’s side, will lock to secure the hood. (Fig. 4) Pull up on the hood actuator strut lock to unlock the strut to allow the hood to close.

Fig. 4

Fig. 4

Brakes

The Bosch TCS8TA brake system uses a Hydro-Max hydraulic brake booster and master cylinder. The system uses DOT 3 Hydraulic Brake Fluid. The system features antilock braking, electronic brake force distribution, drag torque control, and traction control.

The Body Control Module (BCM) monitors the brake pedal position sensor signal to determine the brake pedal position. The brake pressure sensor is used to sense the action of the driver’s application of the brake pedal. The sensor provides an analog voltage signal that will increase as the brake pedal is applied. The Electronic Brake Control Module (EBCM) monitors the brake pressure sensor, which is integral to the brake pressure modulator.

Exhaust Brake

The exhaust brake can be used to enhance the vehicle brake system and reduce brake lining wear by downshifting to increase engine speed. The number of downshifts selected is determined by the length of time the brakes are applied and the rate the vehicle is slowing. Automatic downshifts will not occur if the vehicle is in Range Selection Mode.

The exhaust brake only activates when the transmission torque converter is locked, which varies based on vehicle speed, gear, and load. To activate the system, press the exhaust brake switch in the center stack of the instrument panel. The switch indicator will turn on. Press the switch again to turn off the system. The switch must be pressed at each vehicle start for the system to be active.

Four-Wheel Drive

Four-wheel drive models have manual locking hubs on the front axle. (Fig. 5) The locking hubs must be manually turned to Lock before shifting the transfer case. The hubs may remain in the Lock position when road surface traction conditions vary. When four-wheel drive is not needed, turn the hubs to the Free position. If the hubs are locked when in two-wheel drive, driveline vibration may occur.

Fig. 5

Fig. 5

Use the electronic transfer case knob on the instrument panel to shift into and out of four-wheel drive. The indicator light on the knob flashes while the transfer case shifts and remains on when the shift is complete. If the shift cannot be completed, the transfer case goes back to the last setting. Do not shift the transmission into gear before the indicator light has stopped flashing to prevent possible damage to the transfer case.

All of the lights on the transfer case knob will flash on momentarily when the ignition is turned On. The light that remains on indicates the current state of the transfer case.

Air Ride Suspension

The available rear air suspension provides a smooth ride with a preset, constant frame height. The air springs on the air ride suspension take the place of steel springs and adjust to load changes automatically.

The system can temporarily lower the rear suspension by approximately six inches using the Air Suspension Dump (ASD) switch in the center stack of the instrument panel. Pressing the ASD switch when the vehicle is in Park and the ignition is in the On/Run position releases air supplied to the rear suspension, lowering (dumping) the rear air suspension for loading. The indicator on the ASD switch illuminates. When the vehicle is shifted out of Park, air is filled into the rear air suspension for the proper ride height and the indicator on the switch will turn off. Vehicles with the air suspension have an AUX warning lamp immediately to the left of the ASD switch. The suspension may refill slowly if this lamp is on.

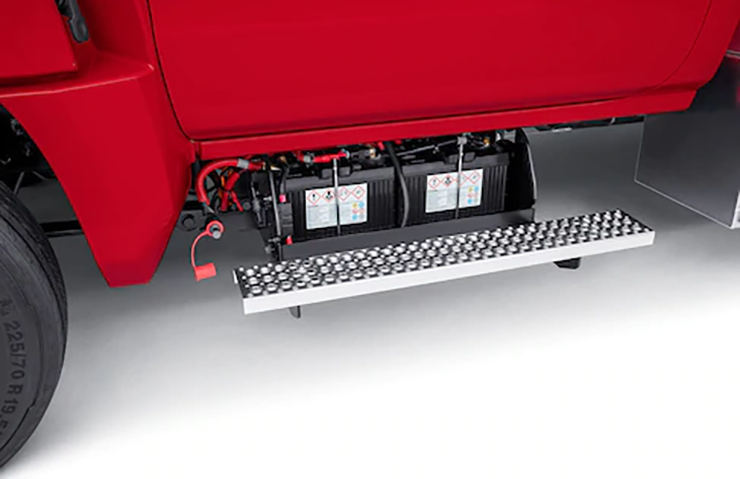

Battery Box

The easy-to-reach battery box (shown with cover removed) is located under the cab on the driver’s side of the vehicle. (Fig. 6) An auxiliary jump-start 12V positive stud with a protective cover is located beneath the driver’s door and to the left of the batteries.

Fig. 6

Fig. 6

In-Vehicle Technology

The available Commercial Link system enables fleet account owners to manage their vehicles and improve overall fleet efficiency. Subscribers to the service can use the built-in OnStar connectivity (must be active) to receive useful vehicle data, such as maintenance notifications and vehicle location, in order to manage mileage and expenses more effectively.

In addition, Silverado chassis cab models offer an OnStar 4G LTE Wi-Fi Hotspot (requires a paid data plan), wireless smartphone charging and Apple CarPlay and Android Auto support.

For additional aftermarket electrical accessories, there are up to four available upfitter switches located on the center stack of the instrument panel that provide 30 amp circuits. (Fig. 7)

Fig. 7

Fig. 7

Some vehicles also may be equipped with a 110/120-Volt AC power outlet. It can be used to power electrical equipment that use a maximum of 150 watts. If equipped with a center console, the power outlet is in front of the cupholders. If equipped with bench seats, the power outlet is on the center stack.

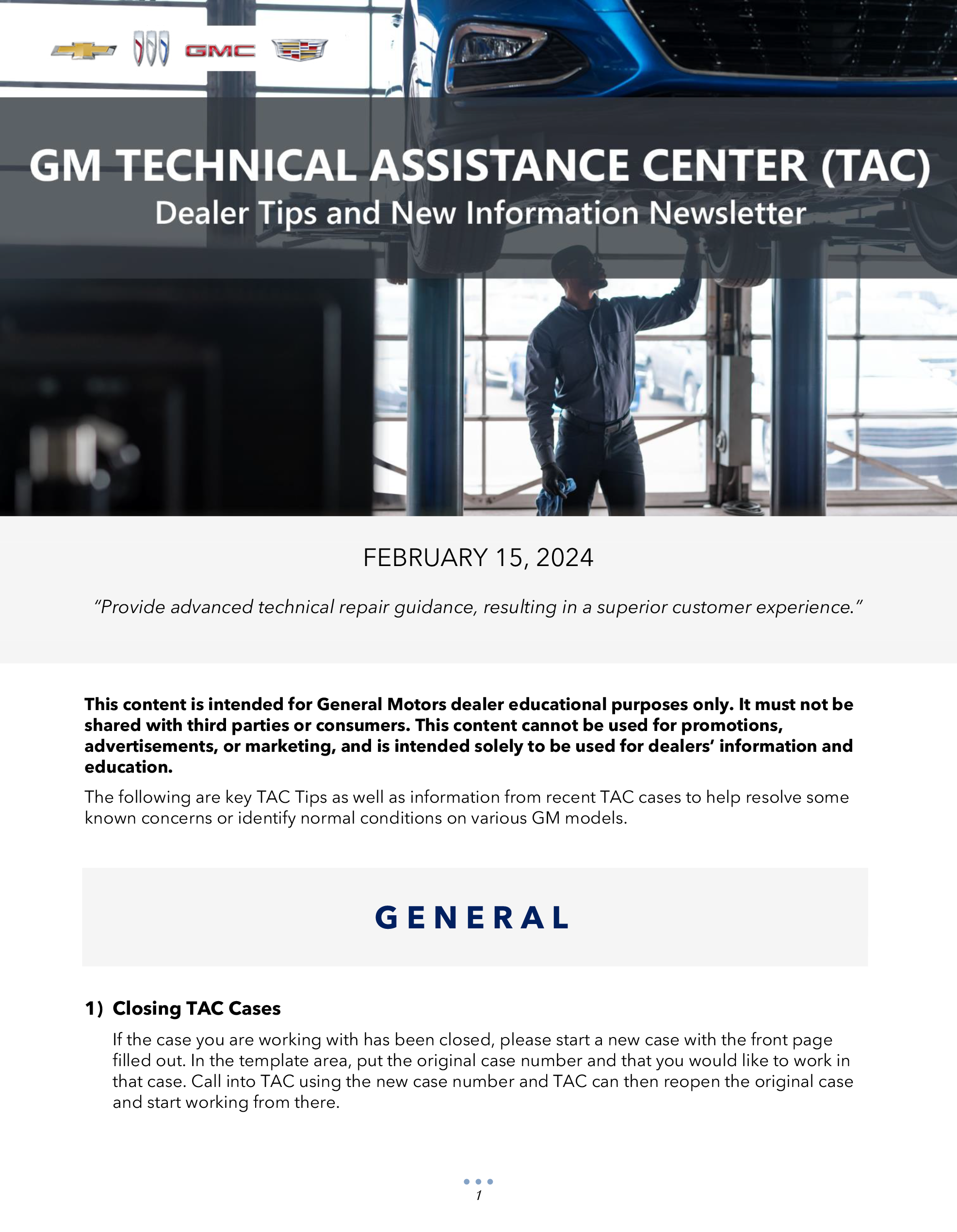

Special Tools

The Service Department will need a 25,000 lb. hoist/lift to raise the vehicle. For safety reasons, do not use jackstands or floor jacks.

The following special tools were released for the 2019 Silverado chassis cab.

| Tool Number | Description |

| EN-52539 | Holder, Fan Clutch Pulley — Engine L5D and L5P |

| EN-52538 | Compressor, Tensioner Strut — Engine L5D |

| J-39197-21 | T&B Flex Connector (incl. J-39197-1 x3) — Electrical for Allison Transmission |

| J-39197-22 | 0.062 AMP Male Connector (incl. J-39197-2 x3) — Electrical for Allison Transmission |

| J-39197-23 | 280 Series Flex Connector (incl. J-39197-3 x3) — Electrical for Allison Transmission |

| J-47277 | 4th Gen TCM Terminal Test Probe (Orange) — Electrical for Allison Transmission |

| GE-52582 | Drain Hose (w/ Quick Connect and Valve) — Engine Cooling |

| DT-52713 | Transfer Case 7-way Breakout Harness — Driveline |

| DT-52709 | Pinion Seal Installer (Front) — Driveline Dana |

| DT-52710 | Pinion Seal Installer (Rear) — Driveline Dana |

| PN 20-2977-2 (8-Lug, 19.5 inch Stud Kit) |

Wheel Balancer Adapter — Will Ship Essential |

| Special Tool Loan Program | |

| CH-52708 | Parking Brake Adjustment Tool — Brakes |

| CH-52707 | Installer / Remover, Bushing (1.35″ O.D.) — Chassis |

| CH-52706 | Installer, 1.39″ I.D. x 1.76″ O.D. — Chassis |

| CH-52705 | King Pin Bushing Service Kit — Chassis |

| DT-52739 | Transfer Case Support Adapter — Transfer Case (Meritor) |

For more information on the new 2019 Silverado chassis cab models, check out the web-based training course 90319.50W: 2019 Medium-Duty Silverado 4500, 5500, & 6500 New Model Features and refer to Bulletin #18-NA-366.

– Thanks to Bob Briedis and Sherman Dixon

why did they put manual locking hubs on the medium duty 4×4?

we need these trucks back in Canada.

When will these be available in Canada?