When performing A/C service on 2013-2019 GM passenger cars and trucks equipped with R-1234yf refrigerant, there are several procedures that must be followed in order to make a proper repair. After warranty repairs are completed, the warranty code on the printout produced by the GE-50300 or GE-50300-A R-1234yf A/C machine is required to be included with the Repair Order.

R-1234yf Refrigerant Systems

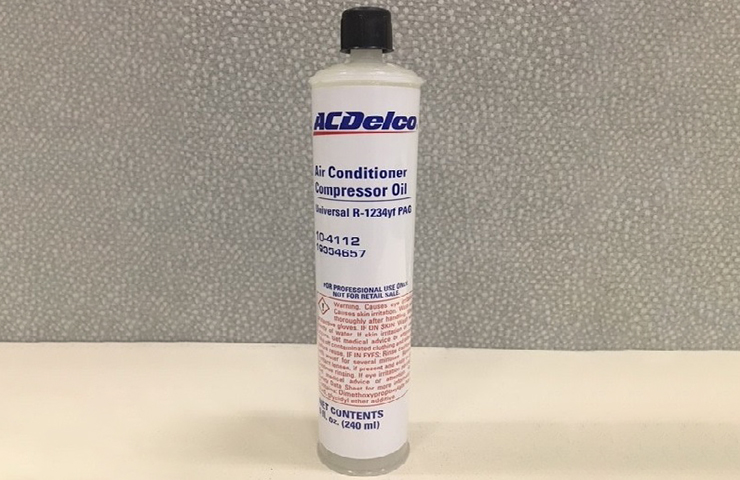

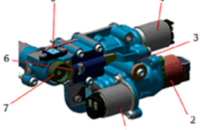

R-1234yf refrigerant systems require the use of specific A/C compressor oils. A universal R-1234yf PAG (Polyalkylene Glycol) oil specifically engineered for GM vehicles with belt-driven A/C compressors is available. (Fig. 18)

Fig. 18

Fig. 18

R-1234yf systems have unique low and high side fittings. Most vehicles using R-1234yf also have an Internal Heat Exchanger (IHX).

To prevent accidental release of refrigerant and minimize safety concerns, the installation of any refrigerant service equipment to the vehicle shall only be done with the engine off and after the refrigerant high side pressure has been reduced (approximately 2–3 minutes).

TIP: R-1234yf is heavier than air and can accumulate in low lying areas like service pits. Always work in a well-ventilated area and never release refrigerants into the atmosphere.

Tools and Equipment

GE-50300 or GE-50300-A Recovery/Recycle/Recharge Machine for R-1234yf A/C Systems (Fig. 19)

- Performs gas analysis prior to gas recovery or fill with recovery/fill lockout if gas is contaminated (< 98% R-1234yf).

- VIN input is required. VIN retrieved via integrated VCI cable connected to vehicles OBD2 connector or manually entered.

- Integrated data recorder with printer that records and prints VIN, pressures, temperature, recovered/charged amount, gas analysis results and encrypts into a warranty code. Warranty code is required to be entered into the comment field of claim for warranty reimbursement.

Fig. 19

Fig. 19

GE-50957 Contaminated Refrigerant Recovery Machine

- Required for recovery of contaminated refrigerant systems.

- To be used with refrigerant recovery cylinders that meet DOT 4BA and TC certification.

GE-50078 Electronic Refrigerant Leak Detection for R1234yf (and R134a)

- SAE J2843 certified equipment (GE-50300) requires a SAE J2913 leak detector to perform the mandated gross leak check.

GE-45037 R1234yf PAG Oil Injection Tool

- To replace PAG oil in R1234yf systems with belt-driven AC compressors. (Use the oil specified in the Service Information.)

- Oil can be injected into a charged system using GE-45037 injector with GE-50744 A/C R-1234yf PAG Oil Injector Hose.50300

Refer to the latest version of Bulleting #12-01-37-001 for additional A/C service information, including details about commercially available recovery cylinders and contaminated refrigerant labels.

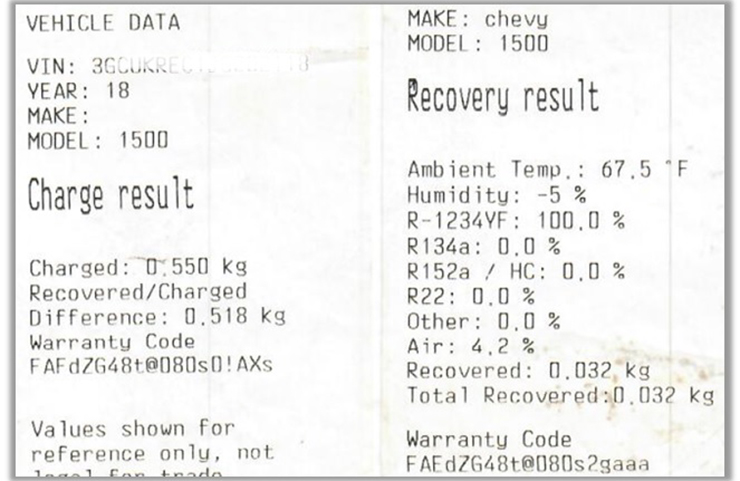

Printout Needed for Warranty Information

A printed summary (Fig. 20) of the completed repair from the GE-50300 or GE-50300-A machine is required to be attached to each Repair Order. The warranty code from the printed repair summary must be entered in the “comment field” of the warranty claim. Warranty claims without the warranty code in the comment field are subject to debit.

GM will reimburse only the R1234yf refrigerant that is actually used (figured by the difference from recovered and charged amount on the printed ‘Vehicle Data’ summary).

Fig. 20

Fig. 20

– Thanks to Charles Berecz and Chad Christensen

Data for the most recently completed function can be printed from the results screen. Additional data is available under the Service Job Data menu.

As long as the job was completed, the machine maintains a record (up to the last 100 records). The job has to be completed or it will not be stored. Check the Service Job Data menu on the machine.

If a reprint is not available, it may be acceptable to take a picture of the retrieved information on the screen for submission.

For more information, refer to the user’s manual or contact Robinair Technical Services at 1-800-822-5561 to go through the retrieval process.

CONCERNING GENE LYNCH’S QUESTION ABOUT REPRINT FOR R1234YF WARRANTY CODE AND INFORMATION, CAN THIS BE DONE AND IF SO WHERE CAN I FIND THE INFORMATION FOR PROCEDURE FOR THIS?

what color should the oil for r1234 be ?. we have 4 different shades of yellow in different tubes from gm (part # 19354657;delco # 10-4112).the latest one that i got was as yellow as a lemon or tracer dye. I call delco and was told that the company that makes it put out a letter that says don’t use yellow oil. they want it back (it took the person at delco to find it, it may have been a engineering note cause he found it after I asked if there were anything like that).so if were not to use yellow oil then what color oil is ok to use.

Can I reprint Printout Needed for Warranty Information if one gets lost.

A smoke machine is not recommended to be used due to the introduction of unknown chemicals into the A/C system. Also, most smoke testing is done at a lower psi, which would likely not have enough pressure to aid in locating the leak. Recommended procedures are outlined in Document ID: 4972081 for R1234yf or Document ID: 4972050 for R1234a.

In addition, the GE-50300-A RRR cart has a feature to allow a small amount of refrigerant to be pre-charged into an empty system (the system must hold vacuum) in order to allow the technician to use either the GE-50078 sniffer or GE-52650 sniffer to help find a small leak. The “test” refrigerant is then recovered once the leak is found.

This is all very good information however, what can a technician do if the dye in the system has washed away before the customer makes it into the dealership? Have had a couple vehicles that has happened to and when performing the vacuum then leak test it fails because the system will not hold. Is there a way to possibly introduce smoke from the EVAP machine to aid in locating the leak? Rather than wasting too much time looking over every component only to tell the customer sorry there’s a leak but I can’t find it. Perhaps there is another way to help locate it? Any information that could help is appreciated.