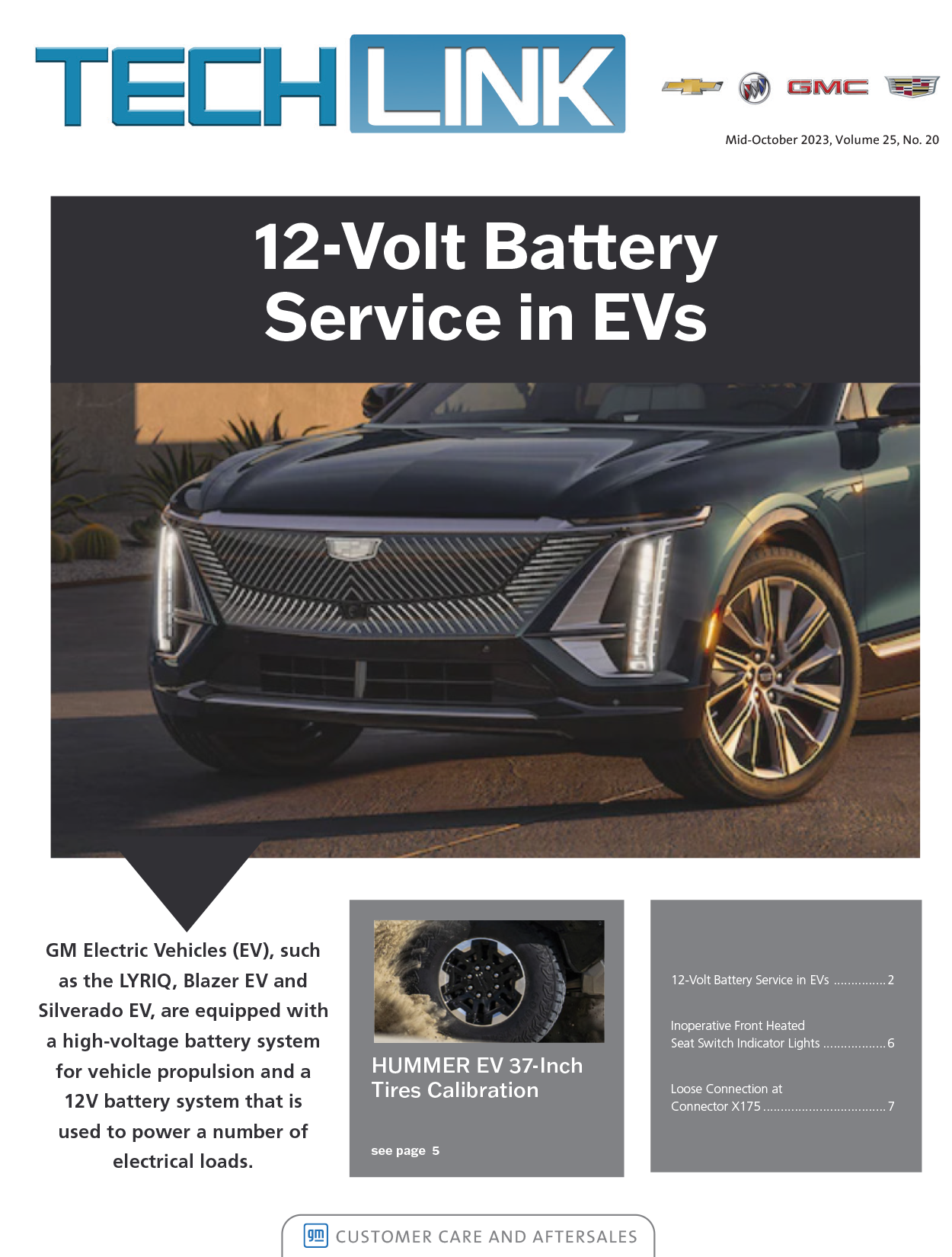

Ever since the Tire Pressure Monitor System (TPMS) was federally mandated (U.S.) in 2008, radio frequencies have been used on GM models to communicate with the system and to determine the location of each TPMS sensor on the vehicle. Today, there are three radio frequencies used in production of GM vehicles.

The new EL-52545 TPMS and RF tool (Fig. 17), which will be shipped as an essential tool to all GM dealerships in the 4th quarter of 2019, features a new communication protocol for TPM systems and Remote Keyless Entry systems. It’s designed to take advantage of the new Next Generation Digital Vehicle Platform electrical architecture coming on the 2020 Corvette, CT5 and CT4 as well as future models. It’s also backward compatible to 2008 and later GM models.

Fig. 17

Fig. 17

The EL-52545 TPMS and RF tool package includes:

- TPMS Module

- USB Cable

- RJ45 Cable

- Power Adapter

- OBD II Module

- Hand Strap

- Storage Case

The EL-52545 tool features a QR code reader to help identify the make and model of a vehicle. It also uses an internal database to determine the proper sensor transmit frequency for a vehicle.

Rotate, Diagnose, Relearn

A recent GM study of 2018 model year vehicle has shown that TPM DTCs C0750, C0755, C0760, C0765 (Tire Pressure Sensor Low Voltage, Too Few Pulses, and Internal Malfunction codes) combined to account for more than 20% of all codes set, most of which set after a maintenance event (tire rotation) or dealer installation of accessory wheels. The EL-52545 tool changes TPMS relearn communication from radio frequency to writing IDs directly via the Diagnostic Link Connector (DLC), which is expected to increase the success and quality of relearn procedures to 100%, without any time penalty when doing a normal tire rotation. As long as the tool is placed by the proper tire, an incorrect sensor cannot be learned, which will greatly reduce the common issue off learning a stray sensor on a near-by vehicle.

The Rotate–Diagnose–Relearn (RDR) function of the EL-52545 tool (Fig. 18) can be used anytime the TPMS or tires are serviced on a vehicle, such as a tire rotation or if the TPMS warning lamp is illuminated. All TPMS data is available on the tool. For example, the tool will highlight a wrong frequency that is deployed in a wheel. And by connecting via DLC, TPMS DTCs that are set can be identified with the TPM IDs learned to the vehicle vs. what is present on the vehicle.

Fig. 18

Fig. 18

Sensor Relearn

Using the tool is easy. Here’s how to quickly relearn the TPMS sensors after a tire rotation. The procedure is a simple process of collecting the sensor data and then providing that data to the BCM.

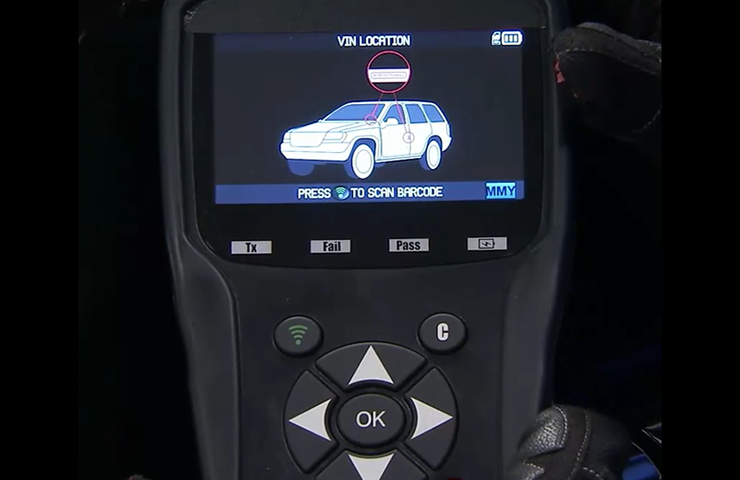

Begin by selecting the RDR function using the tool controls. The vehicle should have the ignition off or in service mode. The VIN screen on the tool will prompt you to scan the vehicle’s QR code, typically found on the Tire and Loading Information label, in order to identify the vehicle. (Fig. 19) Aim the top of the tool at the code. The tool will beep when it has read the code. If the vehicle does not have a QR code, use the tool menu to select the vehicle by make, model and year.

Fig. 19

Fig. 19

Move to the left front tire and place the front edge of the tool against the tire at the valve stem. (Fig. 20) Press the green button on the tool to activate the sensor. The tool will beep once it has the data and will display the sensor information. Repeat the procedure on the right front tire, followed by the right rear tire and left rear tire.

Fig. 20

Fig. 20

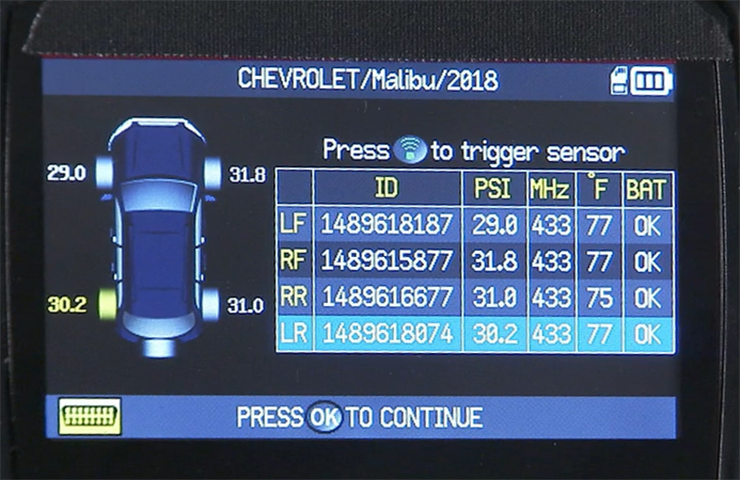

With all four sensors activated, the screen will show the data for each sensor. If the data shown is in white, the tool does not see any frequency concerns with the sensors. (Fig. 21)

Any concerns are highlighted in red. Directions for the next step are shown on the screen.

Fig. 21

Fig. 21

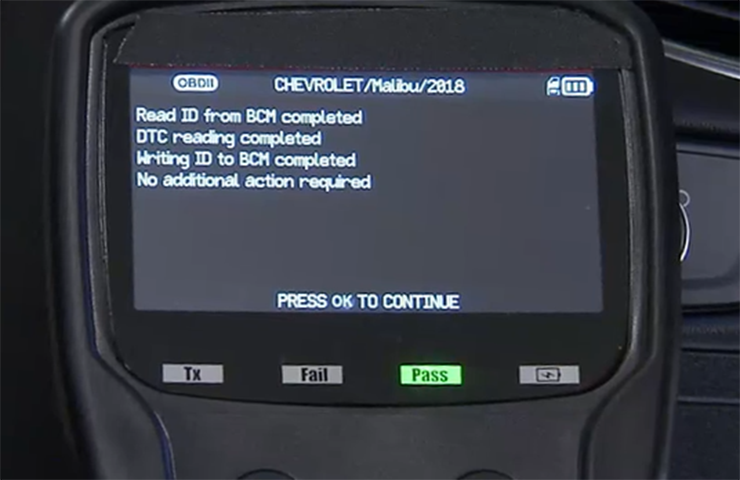

Next, connect the OBD II module cable to the tool and to the DLC in the vehicle. With the vehicle ignition on, engine off, press the OK button and the tool will begin communicating with the BCM and the screen will show a status update. The relearn is complete if the screen displays “No additional action required.” (Fig. 22)

Fig. 22

Fig. 22

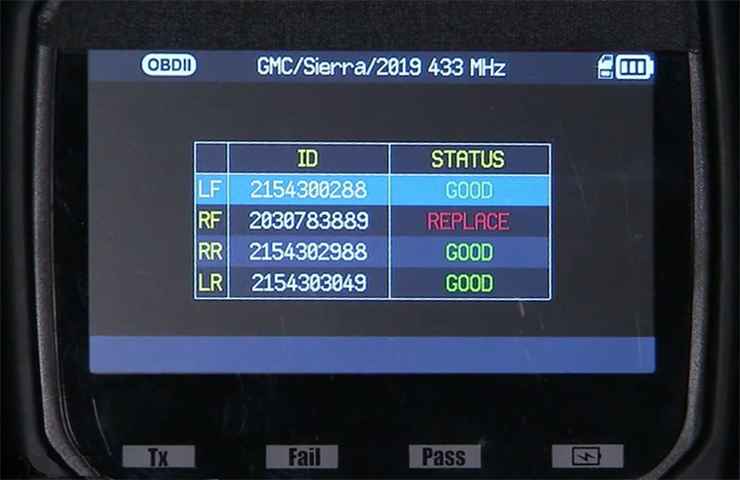

The RDR function ensures that the TPMS sensors are functioning properly as the tool is able to evaluate IDs bolted to the vehicle vs. BCM IDs and malfunction codes. The prescriptive repair direction or clear indication messages (“No additional action required”) on the screen provide concise information on system status as well as next steps. (Fig. 23)

Fig. 23

Fig. 23

Tool Updates

The EL-52545 tool software can be updated to ensure the latest information is being used. As with other tools, the software updates will be available through the gmtoolsandequipment.com website.

Future software releases will add more functionality to the tool, including a new Trailer TPMS feature that can be used to check the Trailer TPM System available on new Silverado and Sierra models.

In addition, the EL-52545 tool has the ability to service non-GM vehicles, supporting the dealership’s used vehicle department.

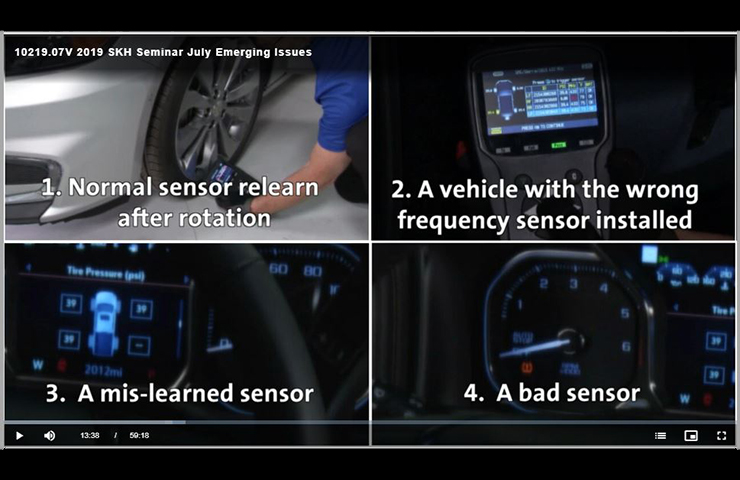

To see the EL-52545 tool in the service bay, check out the July 2019 edition of the GM Service Know-How Emerging Issues seminar, 10219.07V, on the GM Center of Learning website. In Canada, review the August 2019 TAC Talk program. The video covers four typical TPMS situations, including a normal sensor relearn after a tire rotation, a vehicle with the wrong frequency sensor installed on one wheel, a vehicle that learned a stray sensor on a close-by vehicle, and a vehicle with a malfunctioning TPMS sensor. (Fig. 24)

Fig. 24

Fig. 24

Look for more details about the EL-52545 TPMS and RF tool coming soon in TechLink, including a review of the radio frequency functions of the tool.

For more information about the new EL-52545 TPMS and RF tool package (Fig. 25), visit gmtoolsandequipment.com.

– Thanks to Bob Wittmann