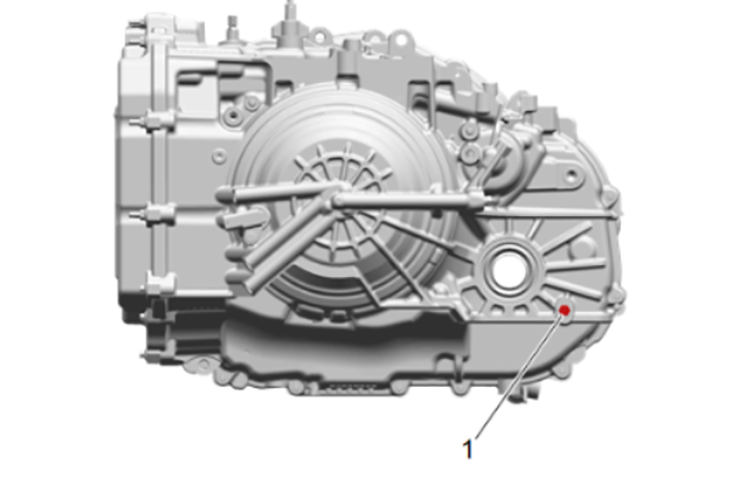

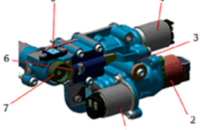

A new replacement program for the 9T65 9-speed automatic transmission (RPO M3V, M3W) (Fig.1) on 2018-2020 Enclave, Traverse; 2019-2020 Blazer; 2020 Acadia, XT5, and XT6 models is being piloted in the U.S. beginning July 1, 2020. The program is designed to reduce the number of days needed to complete vehicle repairs. After diagnosis of an internal fault, technicians are directed to replace the transmission assembly (following the necessary guidelines) instead of making internal repairs to the transmission.

Fig. 1

Fig. 1

The pilot program will run for one year – from July 1, 2020 to June 30, 2021 – and applies to vehicles sold in the U.S. with less than 18 months from date of delivery (DOD) and with under 18,000 miles.

Transmission assembly orders should be coded as CSO order type and not as stock units. Transmission assemblies replaced during the pilot program will be requested by the Warranty Parts Center for engineering analysis. Refer to Bulletin #99-00-89-019S for the part return process.

The repair order for the transmission replacement should include the condition, cause, and correction information as well as details on any DTCs, transmission fluid level, and fluid pressure testing.

- DTCs – include history or current DTCs and the module each DTC was set in. Modules to be searched include the Transmission Control Module (TCM), Engine Control Module (ECM), Body Control Module (BCM), Electronic Brake Control Module (EBCM), Instrument Panel Cluster (IPC), and Transmission Range Control Module (TRCM).

- Transmission Fluid Level – include overfill, under fill, and correct level test results using the fluid level set plug. (Fig. 2) If there is a fluid overfill or under fill, estimate how much.

- Transmission Fluid Pressure – include test results of actual pressure reading taken.

Fig. 2

Fig. 2

Transmission Diagnosis Before Replacement

To determine a repair strategy on a 9T65 transmission – repair or replacement, first review several previously released bulletins covering 9T65 transmission operating and performance conditions. For a complete list of the bulletins as well as other Service Information documents to review, refer to Bulletin #20-NA-136.

Bulletin #20-NA-136 also outlines the necessary steps to take to diagnose 9T65 transmission concerns.

- Check modules for DTCs

- Check the transmission fluid and level

- Check line pressure

- Perform a road test

- Check current DTCs or DTCs that reset during the road test

If diagnosis determines internal components are the root cause or if parts are needed to complete repairs internal to the transmission, the transmission assembly should be replaced and not repaired. The intent of the pilot program is to favor transmission replacement over internal repairs.

Transmission Repairs Allowed

Certain repairs can still be made to the transmission, including:

- Replacement of external seals, including axle, valve body cover, and torque converter seals

- Replacement of transmission oil cooler, lines and accumulator

- Replacement of external mounts

- Replacement of external sensors, plugs, and caps

- Replacement of external transmission controls, including lever, cables, knobs, and module

- Replacement of torque converter assembly

Refer to Bulletin #20-NA-136 for additional information about transmission diagnosis and guidelines for the transmission replacement program.

– Thanks to Mark Kevnick

All Trany times are way out of whack considering how many precision parts there are that have to be in the right place to work. Disassembling a trany always leaves it stuck on a hoist and a cust without a veh for days. I’ve also noticed that tranys are starting to shift like garbage right off the lot so it’s hard to tell if there even is a problem or not

The 9 speeds that ive built I thought paid decent.

I rather build them personally.

YA GOOD DEAL FOR U.S. CUSTOMER .

WHY IS THIS NOT THE SAME FOR CANADA , WE HAVE PARTS HERE TO REPAIR AND GET PARTS FASTER .

SORRY OUR PARTS COME FROM THE U.S.A SO IT TAKES US LONGER TO GET PARTS TO REPAIR . NOT A GOOD DEAL FOR CANADIAN CUSTOMERS . SMALL PIECE OF THE PIE .

AS FOR THE LABOUR TIME THE SYSTEM NEEDS A OVERHAUL IF GM NEEDS TECH’S .

THANK YOU FOR THIS TIME .

ABOVE IS CORRECT first off the internal repair times are way out of line , not just for this unit i am speaking about the c-ks and the 6t70 that time have reduced more than half like almost a third of what they should pay – warranty needs to realize we are running around chasing clocks dealing with lame part people wrong parts parts boxed wrong then the warranty witch with the 3 c’s and the proper repair and oh you cant put a tcm in a overhaul. getting pre auth , and returning the part in the box it came in when it came in a bag – its no wonder there are no transmission techs because they are educated and when the money is wrong see ya . gm needs to get real – most of the old timers like myself would rather do a good job one time than get paid well i think that sums it up.

THIS EXCHANGE SOUNDS REALLY GOOD ON PAPER,BUT IN REALITY THE LIST OF BOLTS THAT CAN NOT BE

REUSED IS VERY LONG,AND THERE IS UP TO A TWO WEEK WAIT TO GET THEM,THIS KIND OF TAKES AWAY

FROM WHAT THIS PROGRAM IS TRYING TO ACHIEVE WITH THE CUSTOMER STILL HAVING TO WAIT ALONG TIME TO GET VEHICLE FIXED AND RETURNED TO THEM?

How about making this the normal on all the transmissions that technicians have had no training on other than watching a video. That may cut the repair time down too. The labor time paid to do internal repairs on transmissions is ridiculous too. Thank you.